Thordon Bearing Materials, a More Reliable Solution for Vertical Turbine Pumps

Thordon Bearing Materials, a More Reliable Solution for Vertical Turbine Pumps

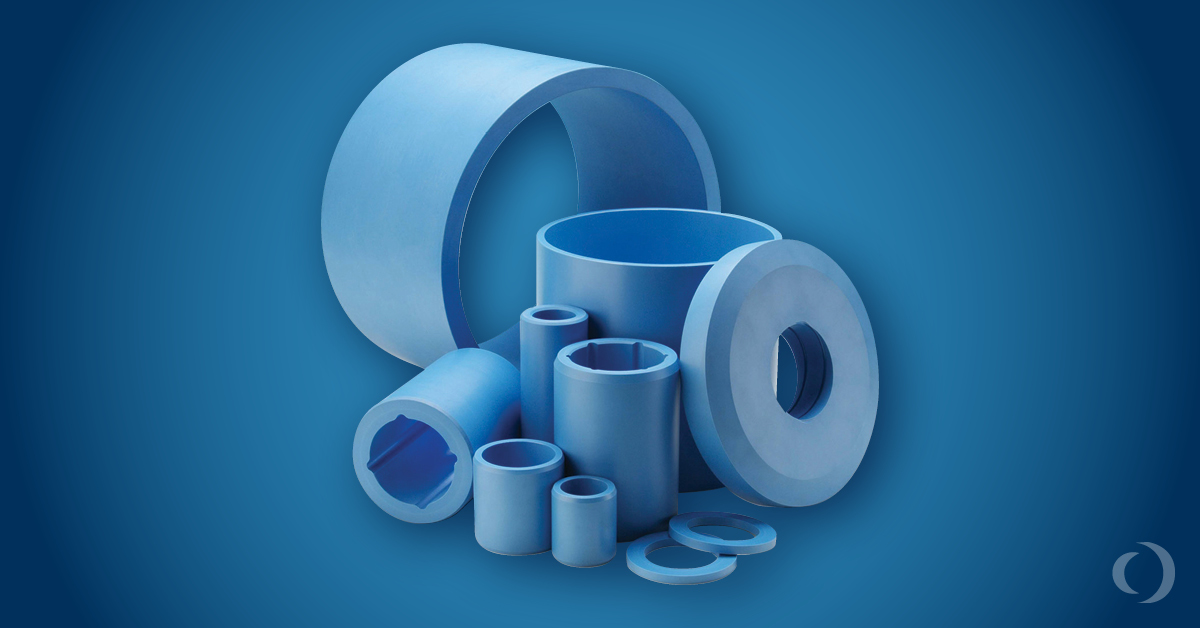

Vertical turbine pumps (VTPs) are critical components in various industries, including water treatment and power generation. Ensuring the reliability and longevity of these pumps is essential for optimal performance and reduced downtime. Thordon Bearings offers a range of bearing materials that provide superior performance and reliability compared to traditional materials like bronze or Babbitt. In this article, we will discuss the unique properties and advantages of Thordon bearing materials for VTPs.

Thordon SXL: High Abrasion Resistance and Dry Start Capability

Thordon SXL has been used successfully in pump bearings for over 30 years and is approved by most pump manufacturers. It offers several benefits:

- Low coefficient of friction, resulting in longer bearing life and reduced start-up torque requirements.

- Excellent abrasion resistance, suitable for demanding applications.

- Greater mechanical strength compared to rubber bearings, allowing for shorter bearing length and improved cooling water flow.

- Easily machinable and installable without the need for metal carriers, reducing costs and delivery time.

- High toughness & resilience, allowing it to absorb impact or shock loads without permanent deformation.

GM2401/Composite: The Bearing Choice for Highly Abrasive Fluids

GM2401 is an excellent bearing material for highly abrasive fluid handling. Its key benefits include:

- Wear rates typically half that of rubber bearings, ensuring longer service life.

- Increased stiffness and resilience compared to rubber, resulting in easier alignment and less edge loading.

- Can be supplied with a 3:1 L/D ratio, which allows for lower friction and cost savings due to shorter length.

ThorPlas-Blue Thermoplastic: High Abrasion Resistance and Enhanced Temperature Rating

ThorPlas-Blue offers several advantages for VTP applications:

- Higher abrasion resistance than most pump bearings and dry start capabilities.

- Enhanced temperature rating of 80°C (176°F) and chemical resistance.

- Minimal water absorption, making it suitable for pumps requiring tight shaft clearances.

- Easy to machine and install, available in finished bearings or tube stock.

- Also available in ThorPlas-White grade, a bearing solution for potable water applications, including NSF and WRAS approvals.

Thordon bearing materials offer a more reliable solution for vertical turbine pumps, thanks to their unique properties and advantages. These materials provide high abrasion resistance, dry start capabilities, resilience, and ease of installation, making them ideal choices for various VTP applications. By choosing Thordon Bearings, you can ensure the longevity and performance of your vertical turbine pumps while reducing maintenance costs and downtime.

Do you have expensive challenges with your bearings and need a creative, cost-effective solution? Allow Millstream Engineering’s team of specialists to lead your group to a successful, economical solution. Contact us today.