All Plastics are Polymers, but Not All Polymers are Plastic!

All Plastics are Polymers, but Not All Polymers are Plastic!

Introduction

In the world of materials science, terminology is of the utmost importance. At Thordon, one of the most common misconceptions encountered is the interchanging use of the terms “plastics” and “polymers.” This might seem like a minor miscommunication, but for those deeply involved in the research, design, and production of these materials, the distinction holds considerable weight.

Plastics vs. Polymers: Setting the Record Straight

Polymers are vast molecules formed by repeating units known as monomers. While they can be either natural or synthetic, they find a plethora of applications ranging from the fabric of our clothes to the very DNA in our bodies. In contrast, plastics represent a subset of these polymers – primarily the synthetic ones. Notably, the ability to mold or shape characterizes plastics.

It’s easy to understand why “plastic” has become somewhat of a catch-all term. Cheap, lightweight, and ubiquitous items like water bottles and food containers have dominated our perception of this material. However, associating the entirety of polymers to such commodity plastics doesn’t do justice to the incredible diversity and capabilities of polymers.

Thordon’s Dedication to High-Quality Polymers

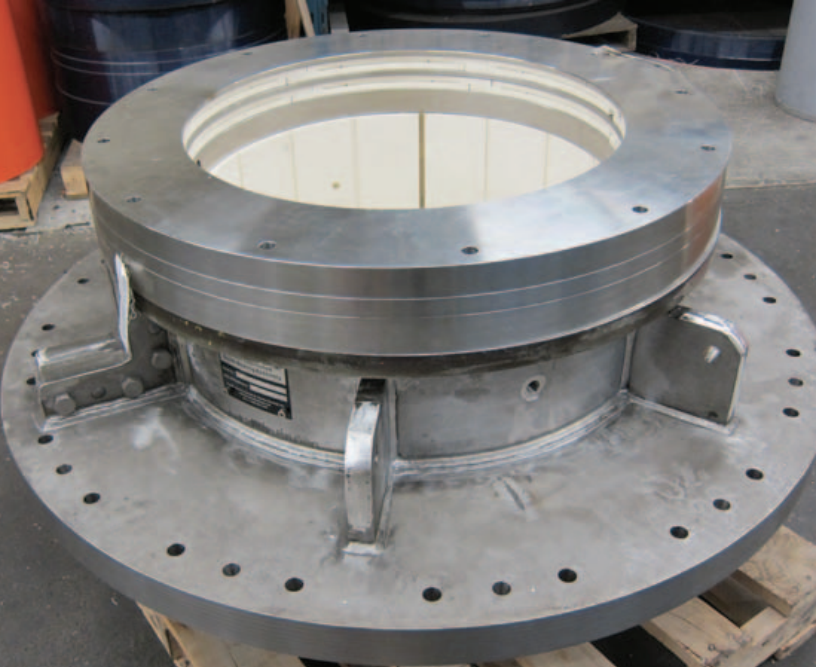

Thordon’s journey began with Sandy Thomson’s innovation of the Thordon SXL elastomer bearing material in the late 1960s. Since then, Thordon’s emphasis has been on engineered polymers, tailor-made to fit unique application needs. The materials Thordon develops exhibit resilience, low wear, and excellent performance, even under challenging conditions. These polymers function seamlessly in wet environments and are designed to last decades, especially in marine applications.

The production of such elite materials isn’t straightforward. Thordon initiates the development process by identifying application needs. Then, based on these needs, they can select the polymer and necessary additives. Rigorous testing ensures that Thordon’s materials live up to the high standards they set, making testing a continual activity in the New Product Development team.

Thordon’s Commitment to Real-World Performance

Thordon products serve some of the most high-profile applications globally. The onus is on Thordon to ensure that these materials stand up to real-world challenges. While laboratory tests are essential, the real proof of the material’s mettle is its performance in actual field conditions. Dedicated test rigs, designed to replicate specific applications, play a pivotal role in the Research and Development process. Moreover, before any full product launch, field trials provide the final stamp of approval.

In conclusion, the next time you come across someone classifying Thordon’s offerings as mere “plastic,” remember the vast difference between everyday plastics and the high-quality polymers that Thordon produces. Thordon stands for excellence, resilience, and innovation – traits that go beyond any ordinary plastic.