Thordon Bearings in the News

Powering Canada’s Hydropower Modernization

Thordon Bearings has been making headlines with its contributions to Canada’s growing hydropower sector, playing a key role in two significant projects that aim to enhance the reliability and efficiency of some of the country’s most critical energy infrastructure.

In Quebec, Thordon Bearings is supplying its state-of-the-art Thorseal brake cups to Hydro-Québec as part of a comprehensive, decade-long turbine brake system overhaul. Hydro-Québec, the largest hydropower utility in Canada, has been focusing on upgrading the turbine brake systems at several of its major power stations, with Thordon’s brake cups at the center of this initiative. The Thorseal brake cups are essential for maintaining the pressure within the braking system that slows and stops the hydro-turbines, which can weigh hundreds of tons.

With 48 Thorseal brake cups already delivered to the Manic-2 station (also known as the Jean-Lesage Generating Station), Thordon Bearings is continuing to supply additional brake cups for other key stations such as Churchill Falls in Newfoundland and Bersimis-2 in Quebec. These high-performance brake cups, made from a proprietary elastomer, offer long-lasting durability, eliminating the risk of cracking and degradation over time. This ensures consistent performance in environments where even minor failures could lead to significant downtime or catastrophic damage.

Learn more about this project and the Jean-Lesage power station here

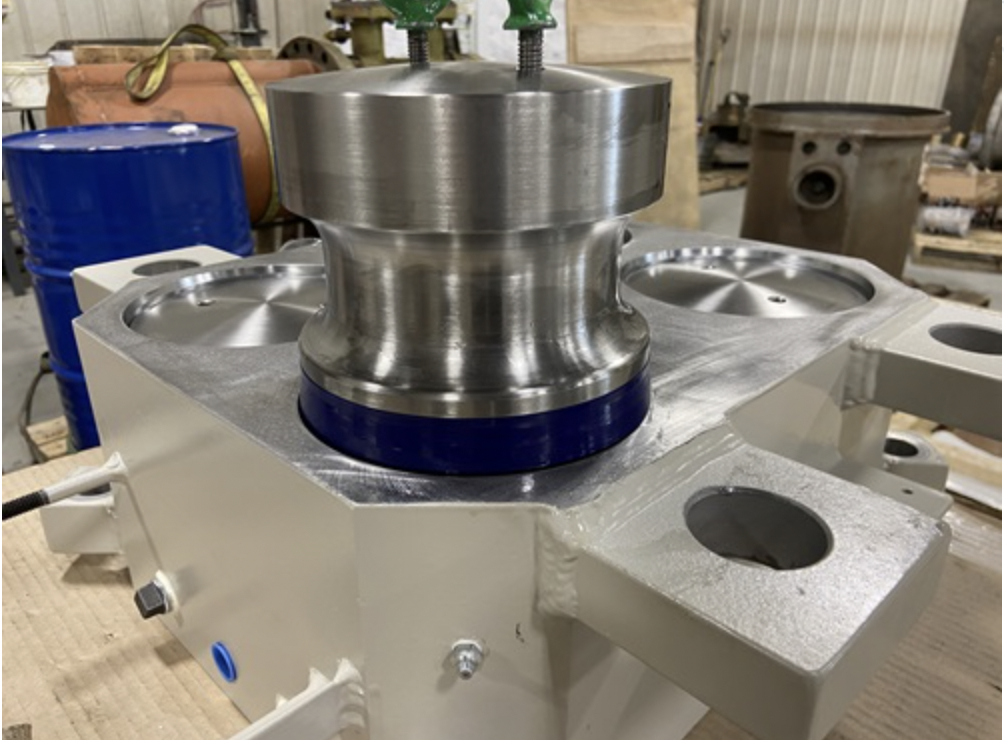

Meanwhile, in Ontario, Thordon Bearings is playing a major role in the refurbishment of the Otto Holden Generating Station on the Ottawa River. As part of a mid-life overhaul of the station’s turbines, Thordon Bearings is supplying a full suite of grease-free bearing solutions, replacing outdated technology with modern, high-performance products. These products include ThorPlas-Blue self-lubricated wicket gate bearings and Thorseal wicket gate seals, which have been installed on two of the station’s eight 243MW units, with more installations scheduled through 2029.

The project, led by Andritz Hydro and supported by Thordon’s local distributors RMH Industries in Quebec and Millstream Engineering in Ontario, is transforming the station’s operational capabilities. The new bearings not only eliminate the need for greasing—reducing both maintenance costs and environmental impact—but also provide enhanced performance under edge-loading conditions. ThorPlas-Blue, a self-lubricating thermoplastic, ensures smooth operation even in limited-motion applications, making it a perfect fit for hydro-turbines that must withstand high pressures and variable loads.

Greg Auger, Commercial Director at Millstream Engineering, emphasizes the precision required for the installation process: “Accurate measurements are critical to ensure the proper fit and clearance of the bearings, as even small misalignments could affect performance.” As hydropower facilities across Ontario undergo modernization, Thordon’s cutting-edge products are helping to extend the life of these assets and improve their sustainability.

The push for hydropower modernization is more urgent than ever as the demand for renewable energy continues to grow. Thordon Bearings’ role in these two key projects demonstrates the company’s commitment to providing high-performance, long-lasting solutions for the renewable energy sector.

Do you want to Learn more about this project and the Otto-Holden power station??

For operators looking to enhance the performance and reliability of their hydropower facilities, Millstream Engineering is ready to help. Whether you need guidance on upgrading your turbine bearings, seals, or other critical components, Millstream Engineering’s expert team can provide customized solutions to meet your specific needs.