Case Studies of Thordon Bearings in Ontario’s Lock Systems

Case Studies of Thordon Bearings in Ontario’s Lock Systems

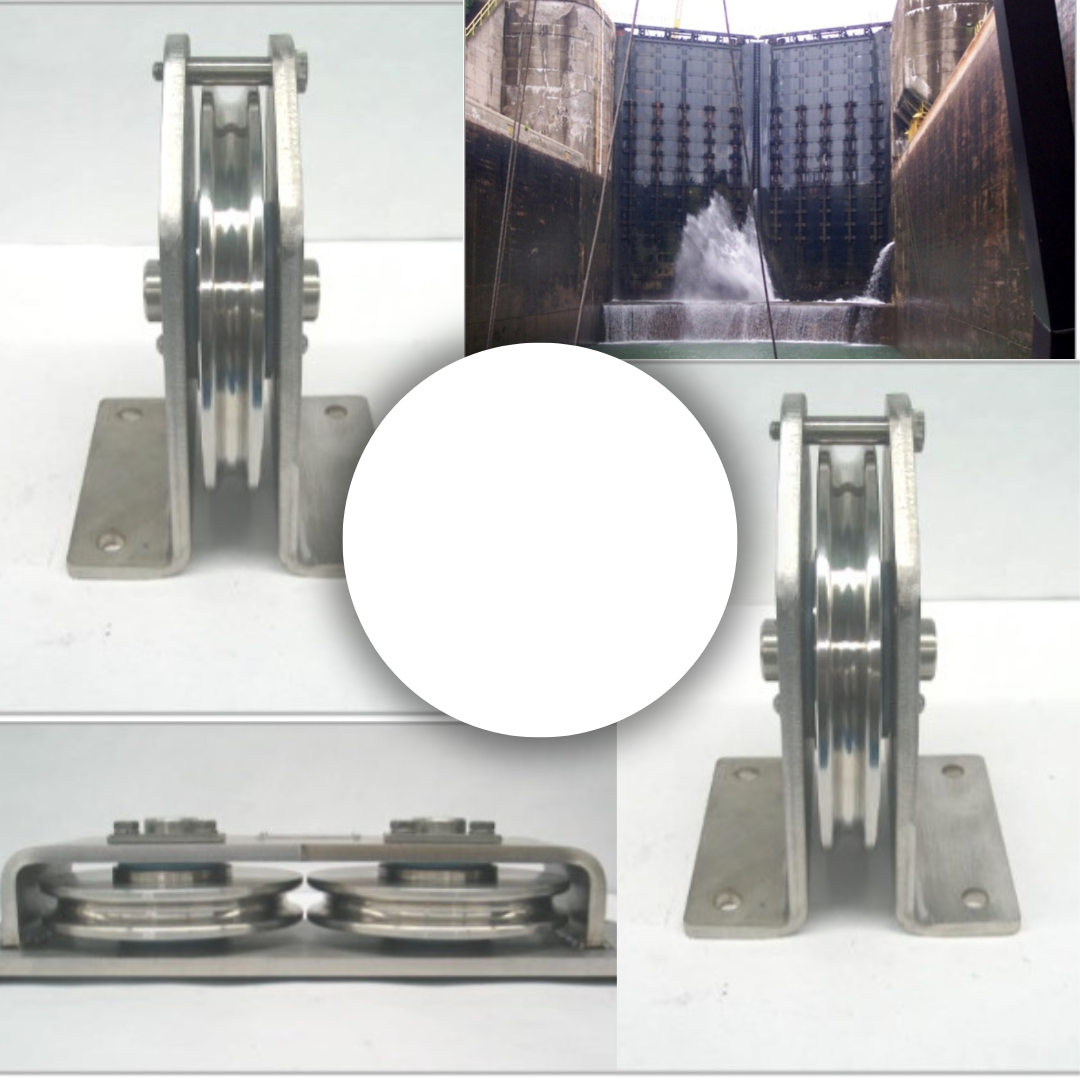

Case Study 1: Sheaves for Opening Doors in the Welland Canal

Application Details

Speed:

<10 RPM

Bearing Pressure:

Over 9.6 MPa (1400 psi)

Installation Date: December 2004 (1st order)

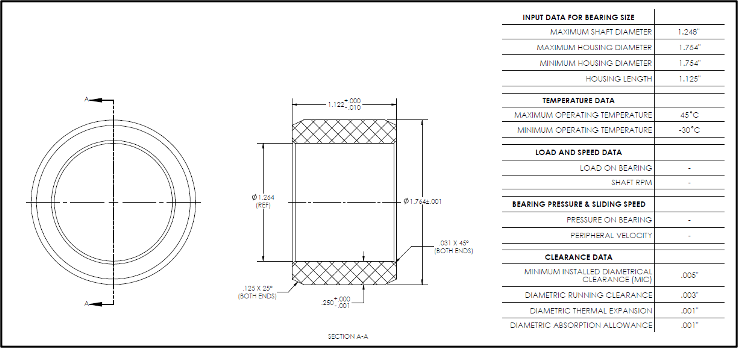

Case Study 2: Kirkfield Lift Lock Equalizing Gate Hinge Bushings

Customer Requirement: The customer sought an alternative to bronze bushings to eliminate the need for grease and reduce maintenance costs. Millstream recommended ThorPlas-Blue material for the bushings due to its superior performance characteristics.

Application Details

Benefits of ThorPlas-Blue:

Welland Canal