What are some common misconceptions about water lubricated bearings?

What are some common misconceptions about water lubricated bearings?

Dispelling Misconceptions About

Water-Lubricated Bearings

Water-lubricated bearings offer numerous advantages over traditional oil or grease-lubricated bearings. However, misconceptions surrounding their use often lead to hesitation in adopting this innovative solution. In this blog post, we will debunk common misconceptions and shed light on the truth behind each, explaining why these beliefs are unfounded.

Misconception: Water-lubricated bearings require frequent maintenance compared to oil or grease-lubricated bearings.

Truth: In reality, water-lubricated bearings require less maintenance. Unlike oil or grease, water is readily available in many industrial processes, and doesn’t require regular replenishment or monitoring. Once properly installed, water-lubricated bearings can operate efficiently for extended periods without the need for frequent maintenance.

Not suitable for high-speed applications.

Misconception: Water-lubricated bearings are not suitable for high-speed applications

Truth: Advancements in bearing design and materials make water-lubricated bearings suitable for high-speed applications. With proper engineering and appropriate water flow rates, these bearings can reliably operate at high shaft speeds without compromising performance or durability.

Cannot handle heavy loads.

Misconception: Water-lubricated bearings cannot handle heavy loads:

Truth: Water-lubricated bearings can handle heavy loads with proper design considerations. The use of advanced materials and well-established design guidelines allow these bearings to provide the necessary load-bearing capabilities, making them suitable for a wide range of applications, including heavy-duty machinery and equipment.

Difficult to install and require specialized expertise

Misconception: Water-lubricated bearings are difficult to install and require specialized expertise, requiring expert knowledge.

Truth: While water-lubricated bearings have unique installation requirements, they are not inherently more difficult to install than their oil or grease counterparts. Qualified technicians can install them with proper training and manufacturer guidance. Technical support is also available to ensure a smooth installation process.

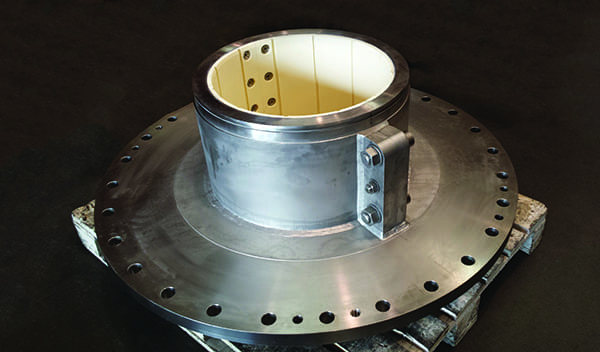

Water-lubricated bearings find applications across various industries, demonstrating their versatility and effectiveness. They are widely used in the marine industry for propulsion shafting, hydroelectric power generation, and a wide variety of Industrial applications.

For the seamless implementation of water-lubricated bearings, Millstream Engineering offers expertise and support. Their experienced team provides tailored solutions, from design to installation and ongoing maintenance, ensuring a smooth transition to water-lubricated bearings. With our support, Industrial equipment designers can confidently embrace water-lubricated bearings, optimizing equipment performance, reducing environmental impact, and ensuring long-term operational success.

Have higher friction compared to oil or grease-lubricated bearings.

Misconception: Water-lubricated bearings have higher friction compared to oil or grease-lubricated bearings reducing their efficiency.

Truth: Water-lubricated bearings are designed to minimize friction and offer excellent lubrication properties. Proper design and adequate water flow keep friction at a minimum. Moreover, water acts as a natural coolant, dissipating heat generated during operation and reducing the risk of friction-related issues.