Hydro Case Study – Upgrade for a Smooth Move!

Hydro Case Study – Upgrade for a Smooth Move!

THE CHALLENGE – Ensure Smooth Gate Operation for Decades to Come

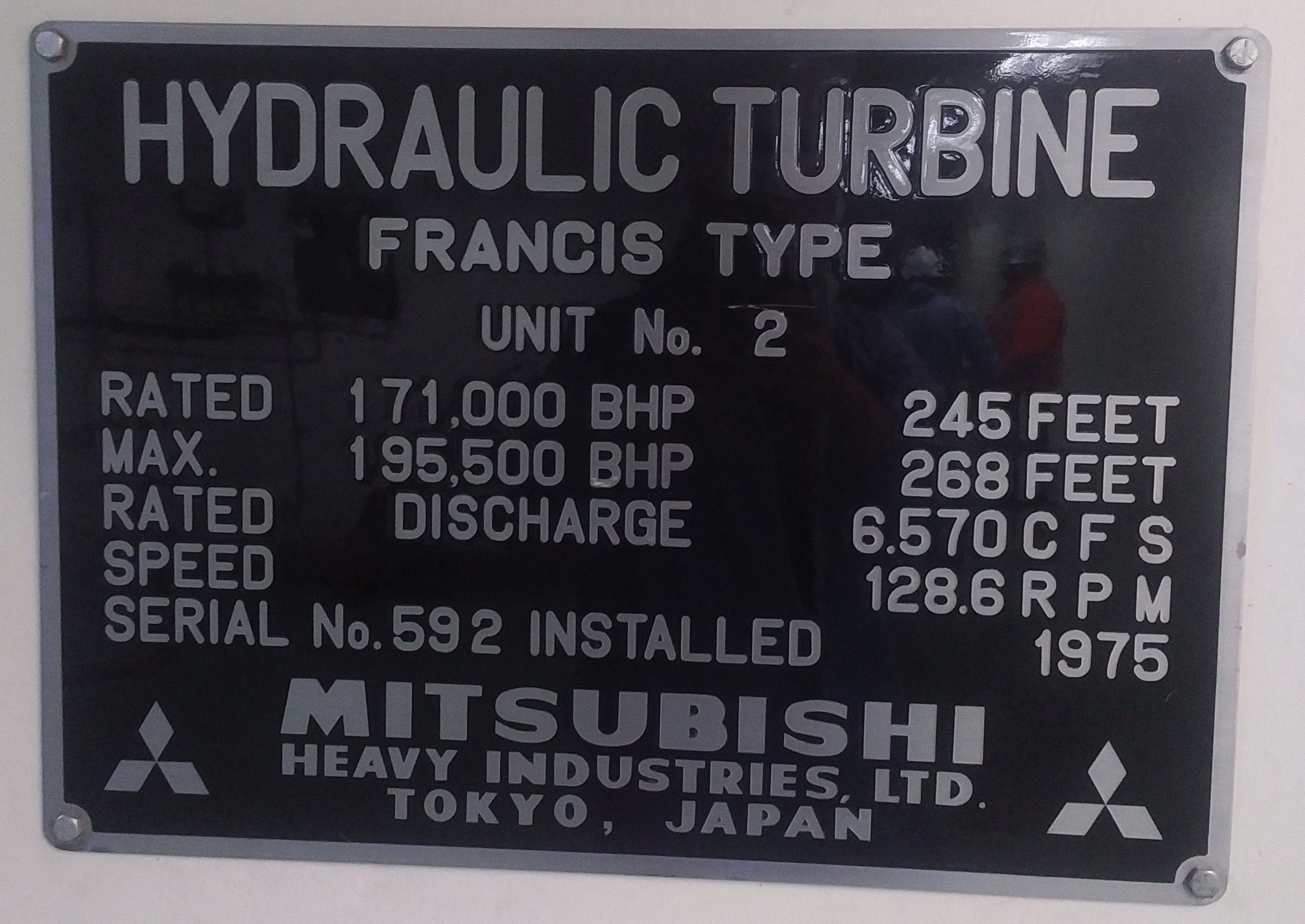

A hydro utility in Western Canada was undertaking an overhaul of one of the vertical Francis units located in a large power station on the Kootenay River. The 132MW turbine had been originally installed in 1975 and most recently overhauled in 1994, so planned work included replacing the Thordon wicket gate bushings and operating ring wear pads that had been providing reliable service for the past 24 years.

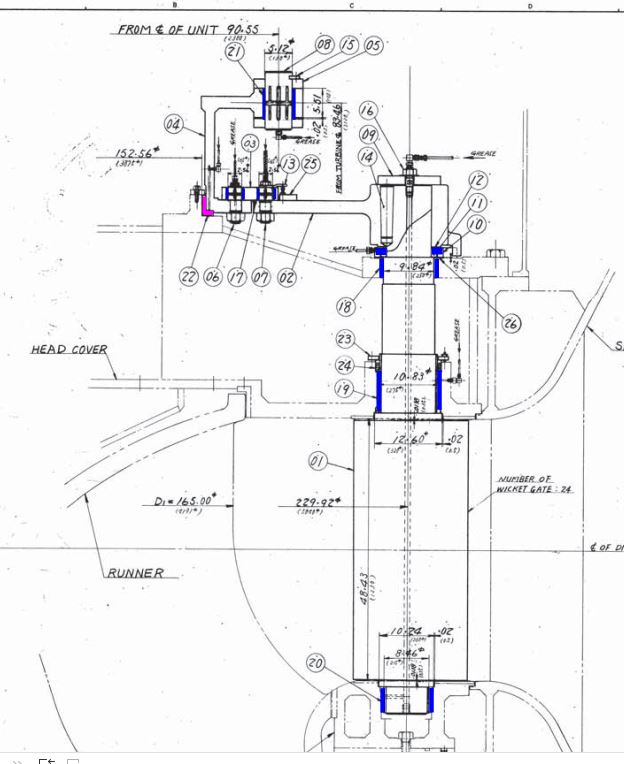

The tight timeline for completing the the outage meant that efficient communication and quick machining of the finished bushings would be critical to the success of the overhaul. Although the wicket gate & linkage bushing replacements would be relatively straightforward, there was some uncertainty about the exact thrust washer thickness that would be required to achieve the proper positioning of each wicket gate, so it was decided to machine the thrust washers locally in the small workshop located in the power station.

Unit Overview

Turbine Nameplate

Bushing Locations to be Replaced

THE SOLUTION – Upgrade with ThorPlas-Blue

The customer’s Engineering staff first contacted Thordon in early 2017 to discuss the project, and after a thorough technical review, the order was placed in late 2017. The new ThorPlas-Blue bushings and Thordon HPSXL wear pads were delivered to the site in early 2018, as well as rough ThorPlas-Blue tube to be used for the thrust washers.

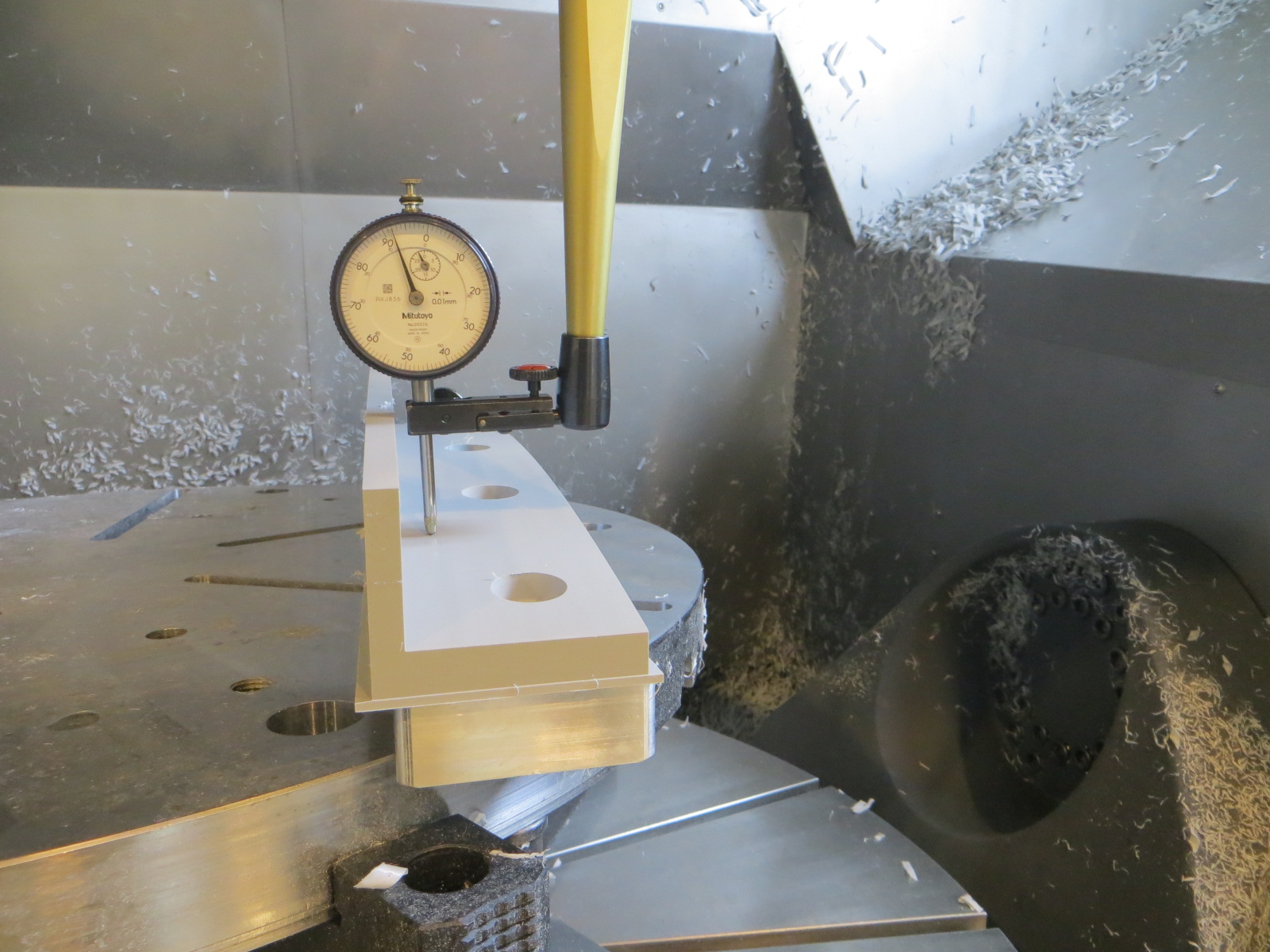

All new components were installed successfully and local staff machined the custom thrust washers from the rough ThorPlas-Blue tube stock to get the exact gate position they needed for optimum blade clearance. The unit was put back in service, and the new ThorPlas-Blue material should provide the customer with smooth wicket gate operation for the next 25+ years!

New ThorPlas-Blue Bushings

Worn Operating Ring Pads

New Operating Ring Pad Machining

Do you have challenges with your bearings, shaft seals, or water filtration systems and need a creative, cost-effective solution? Allow Millstream Engineering’s team of specialists to lead your group to a successful, economical solution. Contact us today.