Kaleshwaram Lift Irrigation Case Study

Kaleshwaram Lift Irrigation Case Study

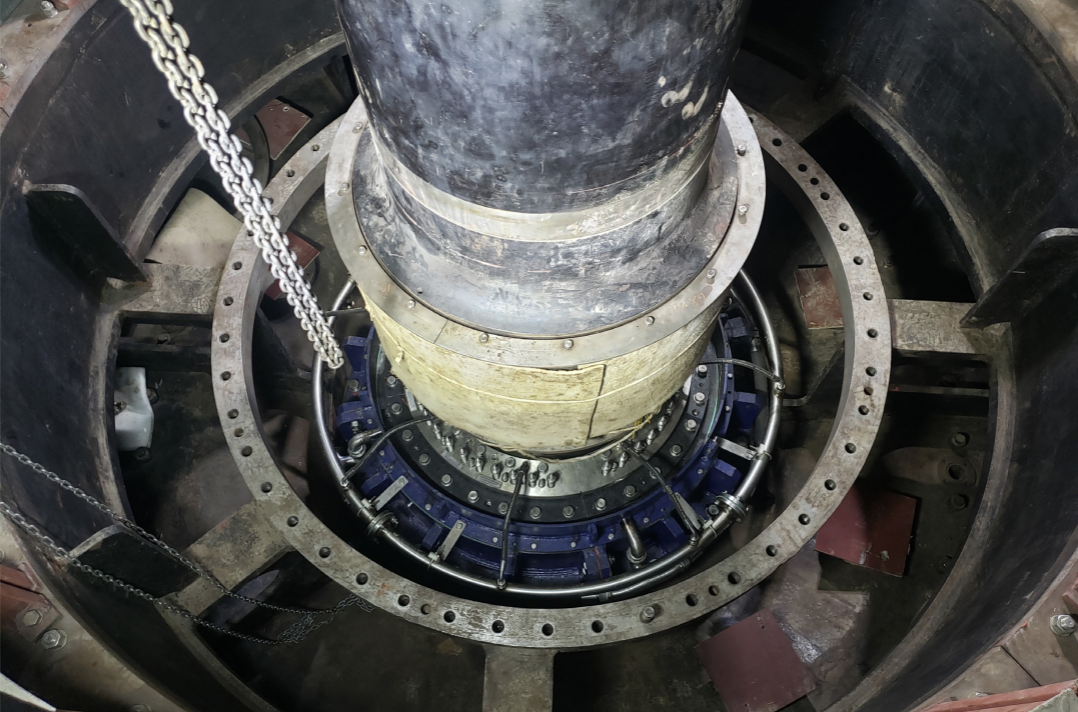

Case Study: How Thordon SXL Seals Ensure Reliability in the Kaleshwaram Lift Irrigation Scheme

The Challenge: Managing Leakage in Large Turbine Pumps

The Solution: Thordon SXL Seals

High wear resistance

Designed to withstand abrasive environments, Thordon SXL’s elastomeric properties allow it to handle particles within the water without significant wear, increasing the lifespan of the seal.

Reliable sealing capability

The segmented design of the SXL seals ensures they can effectively manage water leakage, even in high-pressure environments.

Long service life

rawing from previous installations in similar applications, these seals are expected to last a minimum of 10 years in the harsh conditions present at KLIS.

The Installation and Results