Self-Lubricating Bearings

High Performance Bearing Materials Free From Grease & Oil

Impressive Load Capacity With Low Coefficient Of Friction

A comprehensive range of materials from Thordon Bearings can be designed to replace greased bronze, conventional roller bearings, wear pads, and more.

Self-Lubricating Materials from Thordon Bearings

|

Thordon SXL |

Thordon HPSXL |

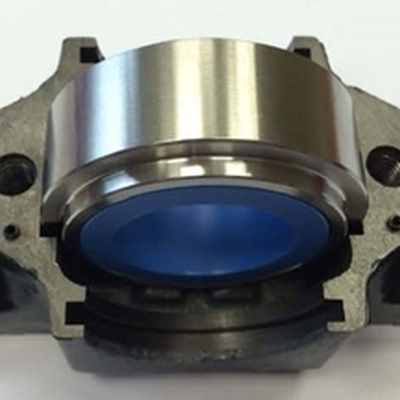

ThorPlas-Blue |

|

| Material Description | Elastomeric Polymer Alloy | Elastomeric Polymer Alloy | Engineering Thermoplastic |

| Coefficient of Friction | 0.10 – 0.20 | 0.08 – 0.15 | 0.10 |

| Young’s Modulus | 605 MPa (88 ksi) | 925 MPa (134 ksi) | 2930 MPa (425 ksi) |

| Temperature Limit | 60°C (140°F) | 60°C (140°F) | 80°C (175°F) |

| Design Bearing Pressure (low speeds) | 10 MPa | 15 MPa | 45 MPa |

| Forms Available | Tube, Rod, Sheet, Block | Tube, Rod, Sheet, Block | Tube, Rod, Sheet |

| General Remarks | Best all-around combination of abrasive resistance, low starting friction, long wear life. | Similar to SXL, but with higher bearing load capacity. | Best choice for lowest sliding friction and highest load capacity. |

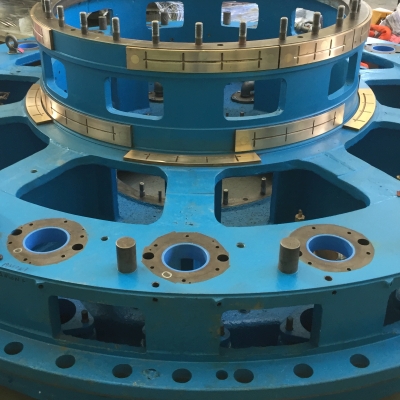

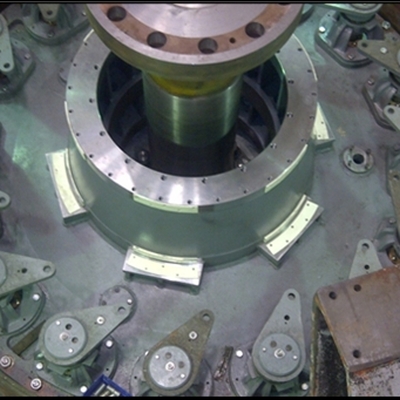

Grease-free Solutions for Low-speed Sliding or Rotating Applications

Eliminate Greased Bronze from Wicket Gates and More

General Design Guidelines

Bearing Pressure

Bearing pressure is calculated by considering the bearing load over the contact area, and each material grade will have a maximum design limit to ensure long and reliable bearing wear life.

Sliding Speed

Sliding speeds create friction heat in the bearing, but in the low speed oscillating or rotating applications pictured here it is rarely the limiting factor in design. Provide an estimated bearing load and sliding speed, and the Millstream team can easily check this for you.

Wall Thickness

Minimum wall thickness is determined by the interference fit required to secure it within the housing, but should not be less than the minimum recommended amount for any given size. The wall thickness of the bearing also influences bearing clearance, since thermal expansion and water absorption allowances are proportional to the wall thickness. A thicker bearing wall will expand and contract more with water absorption or thermal expansion effects, so when possible, it is recommended to minimize the wall thickness to achieve a tighter clearance.

Mating Surface

The mating surface should be made of a corrosion resistant metallic material, with a hardness in the range of 20 Rockwell C when possible. The surface finish of the mating surface should be reasonably smooth according to good machining practice; for optimum performance with Thordon materials, a surface finish of 0.8 micro-meters (32 micro-inches) is recommended.

Fitting Methods

Polymer bearings are usually fitted with an interference fit or bonded using an epoxy adhesive. If interference fitting is used, it is easiest to freeze fit the bearings. In cases where freeze fitting is not possible, bearings can also be press-fitted.

Machining Tolerances

Polymer bearings do not necessarily need to be machined to the same tight tolerances as metal bearings to achieve optimum performance. Consult Millstream for correct bearing sizing and machining tolerances for your application.