Shaft Sealing Solutions

For Hydro Turbine Applications

Keeping The Water Where It Should Be

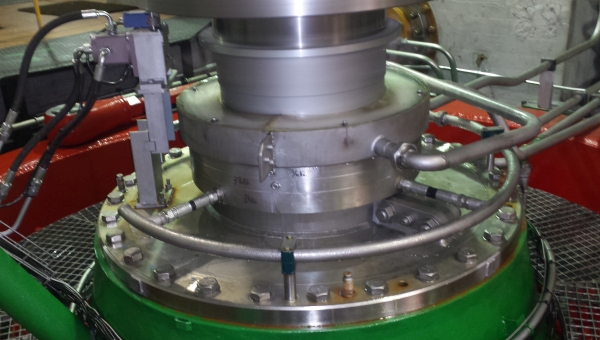

Shaft sealing in hydropower poses many challenges, including high rotating speeds, large diameter shafting, high water pressures, vibration, and high-reliability expectations. Shaft seals utilizing Thordon SXL sealing faces are a great solution.

Elastomeric Thordon SXL Shaft Seal Face Material

|

Thordon SXL |

|

| Applicable Seal Types? | Axial, Radial, Labyrinth |

| Filtered Water Supply? | Recommended filtration to remove abrasives larger than 100 micron size |

| Sealing Face Material | Self-lubricating Elastomeric Polymer Alloy |

| Size Limitation? | No, segmented designs for shaft sizes from 200mm up to 2m+ |

| General Remarks | Best all-around combination of abrasive resistance, low starting friction, long wear life. |

| Resistance to Abrasives? | Excellent |

General Design Guidelines

Mating Surface

The mating surface should be made of a corrosion resistant metallic material, with a hardness in the range of 20 Rockwell C when possible. The surface finish of the mating surface should be reasonably smooth according to good machining practice; for optimum performance with Thordon materials, a surface finish of 0.8 micro-meters (32 micro-inches) is recommended.

Sealed Water Pressure

Axial and Radial type seals are capable of sealing high pressures, but require careful consideration of design parameters, including seal face balancing, water flow, and seal face geometry. Consult Millstream Engineering to get an expert recommendation for your application.

Sliding Speed

The sliding velocity or peripheral shaft speed is an important factor used to evaluate the frictional heat generation in the shaft seal, which will determine the minimum cooling water flow rates required.

Fitting Methods

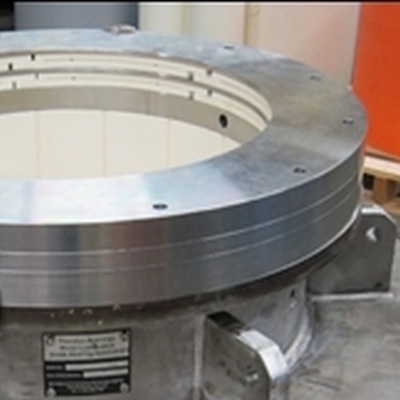

Seal segments are normally installed within a metal housing and may include backing plates, springs, spacers, wear indicators, or other mechanical components. There are many seal designs on the market, so it is best to consult the original technical drawings and operating manual for the shaft seal to ensure it is assembled correctly.

Machining Tolerances

Polymer sealing faces do not necessarily need to be machined to the same tight tolerances as carbon or graphite seal faces in order to achieve optimum performance. Consult Millstream for correct sizing and machining tolerances for your application.

Lubrication Grooves

Lubrication grooves are machined or molded in the seal segments to help the flow of water through the working face of the seal. The grooves also provide a pathway for water to be delivered directly to the sealing interface to help develop a hydrodynamic fluid film between seal face and shaft surface.