Tribology is the interdisciplinary science that examines how surfaces in relative motion interact. It combines principles of physics, chemistry, materials science, and engineering to understand and address three key aspects:

- Friction: The force resisting relative motion between two surfaces. Managing friction is essential for energy efficiency and component longevity.

- Wear: The gradual removal or deformation of material due to mechanical action. Excessive wear can lead to equipment failure and increased maintenance costs.

- Lubrication: The application or inherent properties of materials that reduce friction and wear by creating a protective layer between surfaces.

By understanding these principles, engineers can design materials and systems that operate efficiently, reliably, and sustainably.

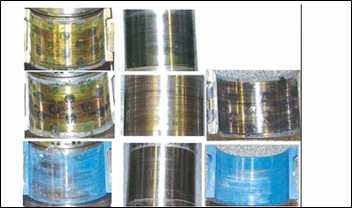

Bearings and bushings —critical components in machinery—are directly impacted by tribological principles. The performance of bearings depends on how well friction and wear are managed. Here’s how tribology influences the development of self-lubricated materials:

Testing and research has revealed several critical factors that enhance the performance of self-lubricated bearings:

- Surface Texture Is Important: Micro-level surface profile can significantly influence friction and wear.

- Material Compatibility: The interaction between the bearing material and the mating counter-surface must be optimized to avoid excessive wear.

- Environmental Factors: Temperature, humidity, and exposure to contaminants all influence how materials behave with respect to friction and wear.

By accounting for these insights, engineers can create self-lubricated bearings that perform exceptionally well across a variety of conditions.

Tribology is an evolving field with exciting advancements on the horizon. Research is focusing on:

Tribology may sound complex, but its principles are the foundation of reliable, efficient machinery. By focusing on friction, wear, and lubrication, engineers can develop solutions that extend the life of components, reduce maintenance, and optimize performance.